Projects

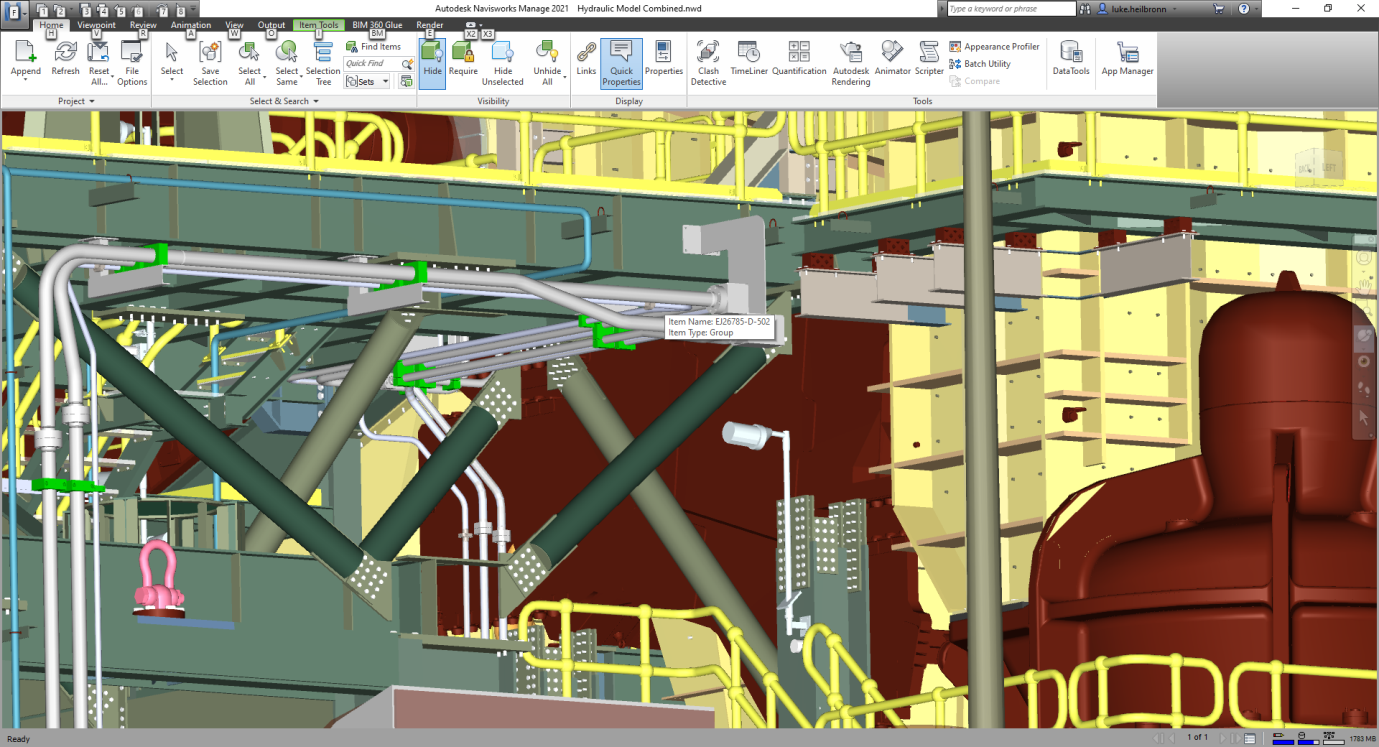

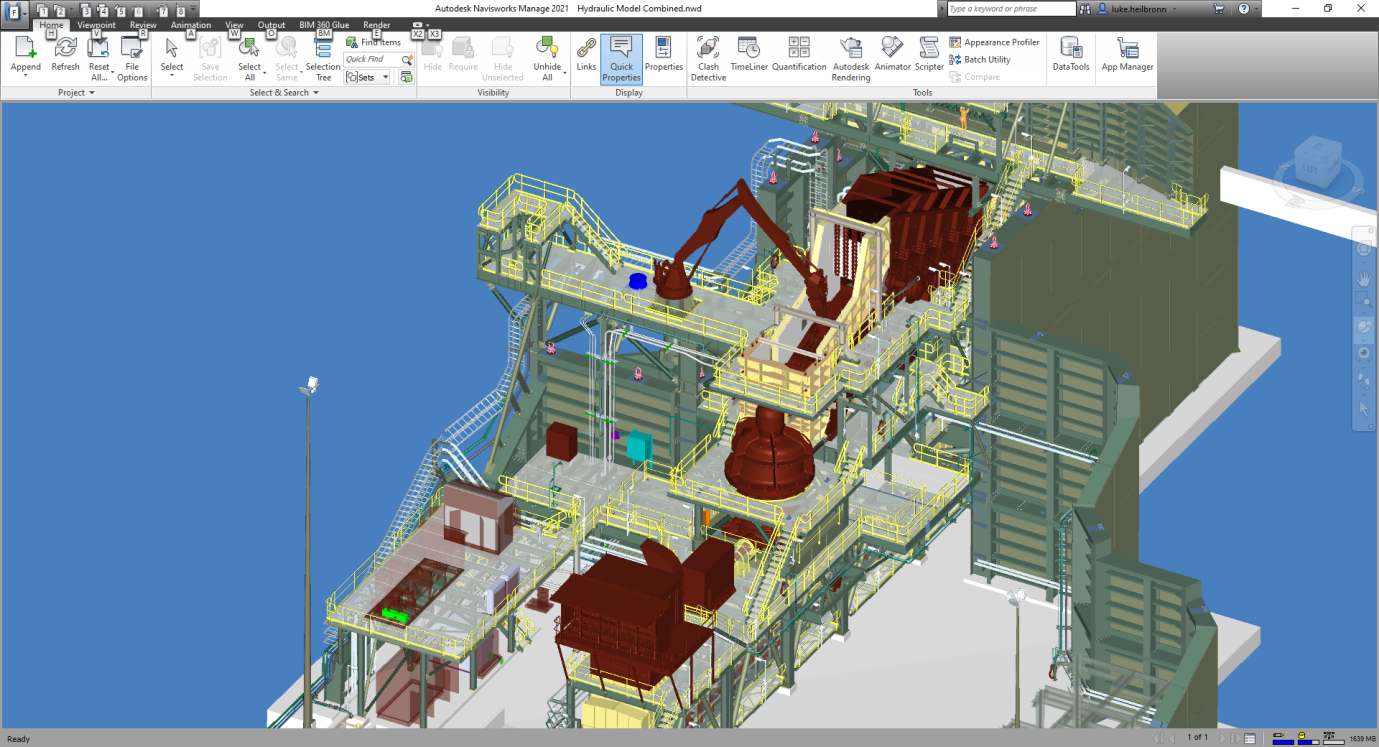

UGL : Royhill ROM 3 Crushing & Conveying: Supply of Equipment Hydraulics and Lubrication Piping

Completion: January 2021 Industry: Mining

Scope of Work

Engineering and Design of hydraulic, cooling, lubrication piping, and supports. Establish pipe routes and provide 3D models within the overall Client’s master model. Provide GA drawings for all piping and supports.

Project management, planning, monitoring and reporting.

Fabrication and supply of all Apron Feeder hydraulic piping, including tube, fittings, clamps, support brackets, hoses, manifolds and other components.

Fabrication and supply of all Crusher hydraulic and lubrication piping, including tube, fittings, clamps, supports, hoses, and other components.

Fabrication and supply of all Rock Breaker hydraulic piping, including tube, fittings, clamps, supports, hoses, and other components.

Factory testing, NDE, surface preparation, painting and delivery to site.

Installation of all piping and supports on site within the project schedule.

Hot oil flushing of hydraulic systems on-site to target cleanliness value.

Completion of final connections, ITP, QA documentation and MDR.

The time scale for this project was very compressed from the beginning. However, Hytube was able to offer solutions to reduced lead times, and was able to manage the schedule due to the ability to complete all scope in house. Apron Feeder piping fabricated and welded 114.3 pipe, schedule XXS.

Design pressure 350 Bar, test pressure 525 Bar.

Mo Group : Press Upgrade – New HPUs and piping.

Completion : December 2020 Industry : Mining

Design of two new hydraulic power units to operate an existing press (similar operation method to that previously supplied by Hytube). The design requirement was to reduce leaks, reduce wear, reduce heat generation and power consumption with non-continuous operation of equipment. Lower operational costs and reduced maintenance, within allocated budget.

Hydraulic Press system pressure up to 350 Bar, custom designed and manufactured hydraulic manifold blocks to include improved operation and additional functions.

Supply and installation of water, hydraulics and lubrication piping on all machines.

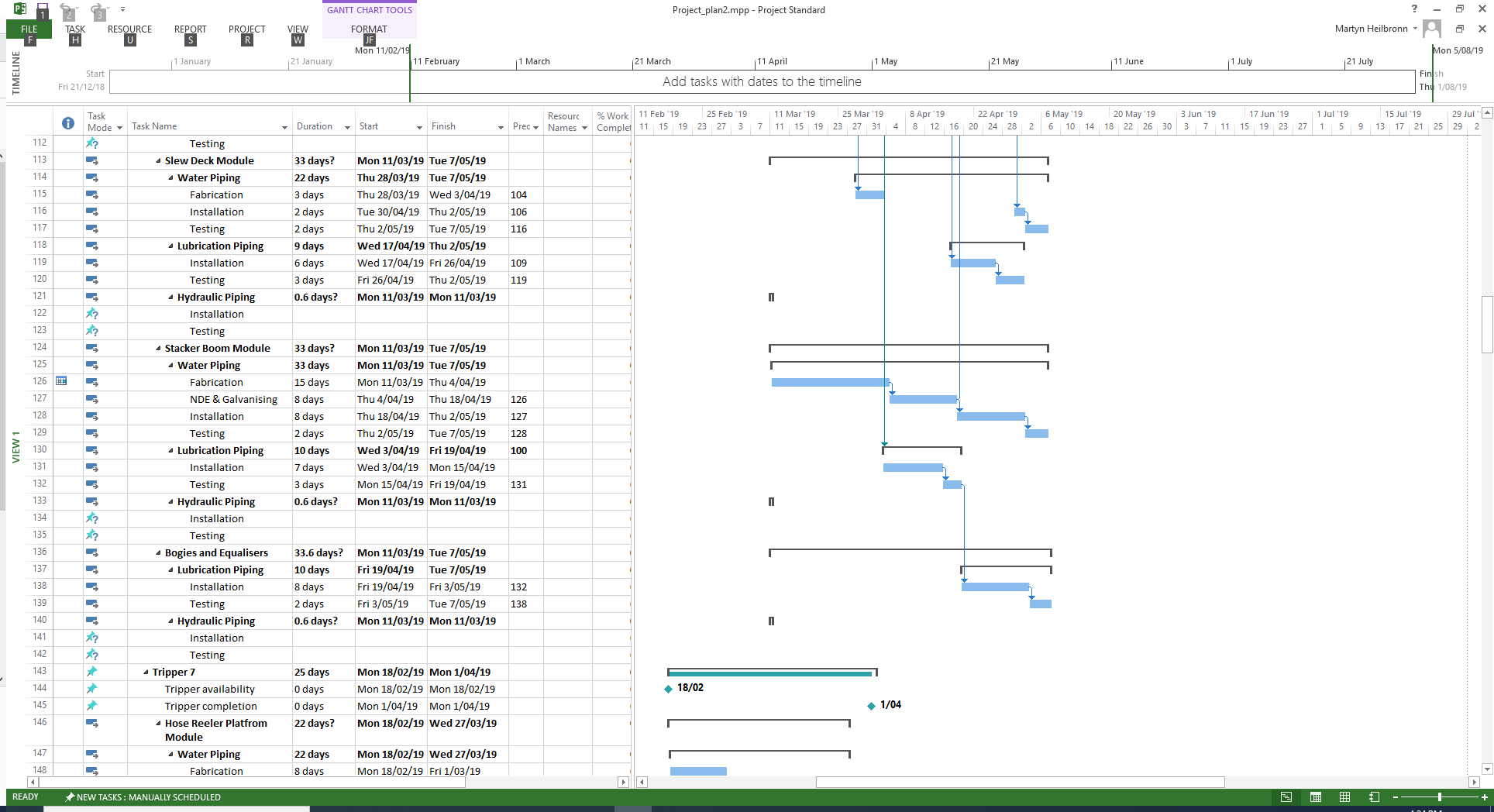

Completion: December 2019 Industry: Mining

Scope of Work

Project management, planning, resource allocation, monitoring, cost control and reporting.

Fabrication and supply of all hydraulic piping, including tube, fittings, clamps, support brackets, hoses, manifolds and other components.

Fabrication and supply of all lubrication piping, including tube, fittings, clamps, supports, hoses, and other components.

Fabrication, galvanising, and supply of all water piping, including tube, fittings, clamps, supports, hoses, and other components.

Factory testing and delivery to site.

Installation of all piping on site to the project schedule.

Hot oil flushing and pressure testing of all hydraulic systems on site to target cleanliness value.

Pressure testing and purging of all lubrication lines on site.

Pressure testing and flushing of all water pipes on site.

Completion of final connections, ITP, Test and flushing diagrams/records, QA documentation and MDR.

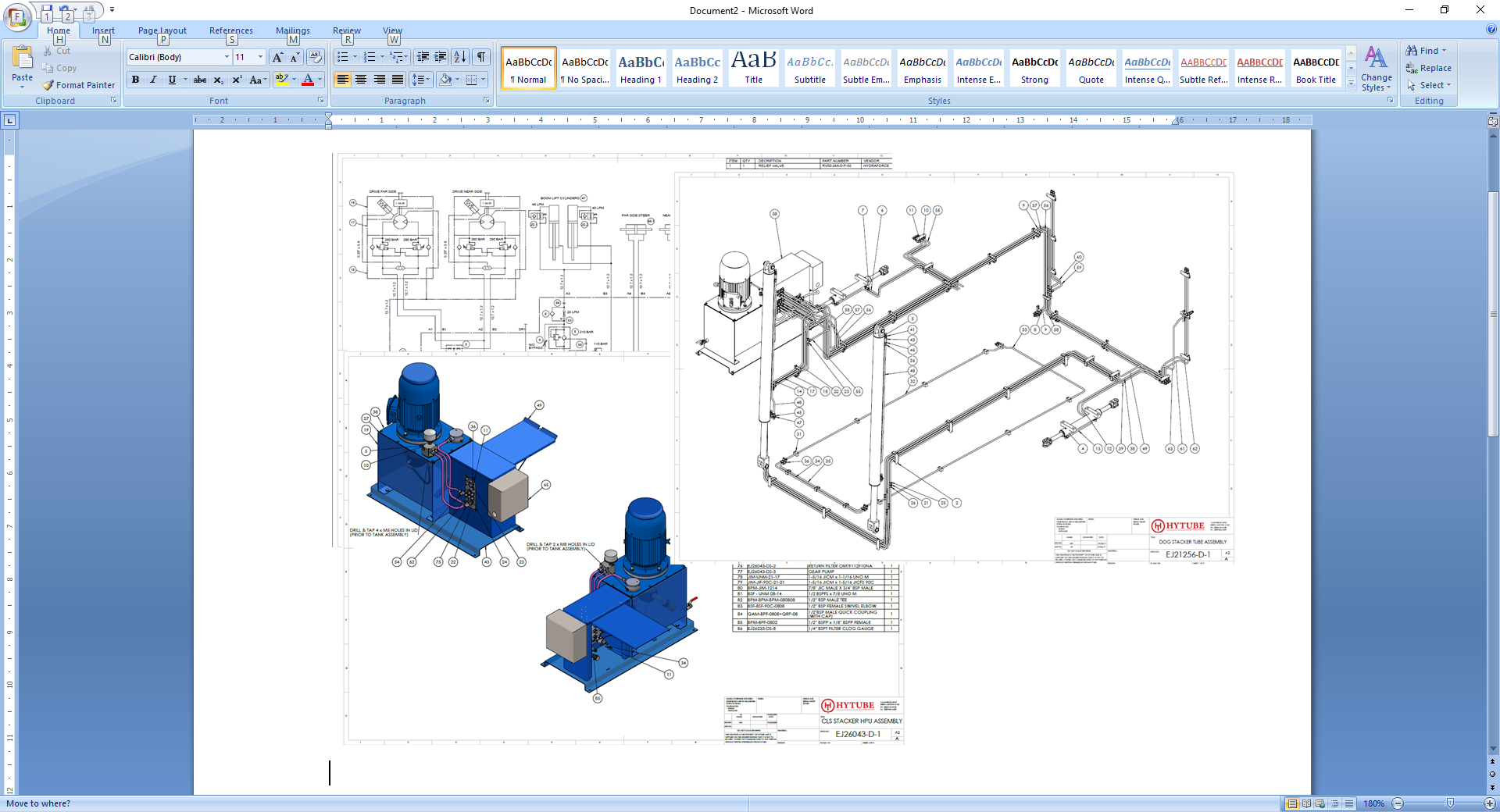

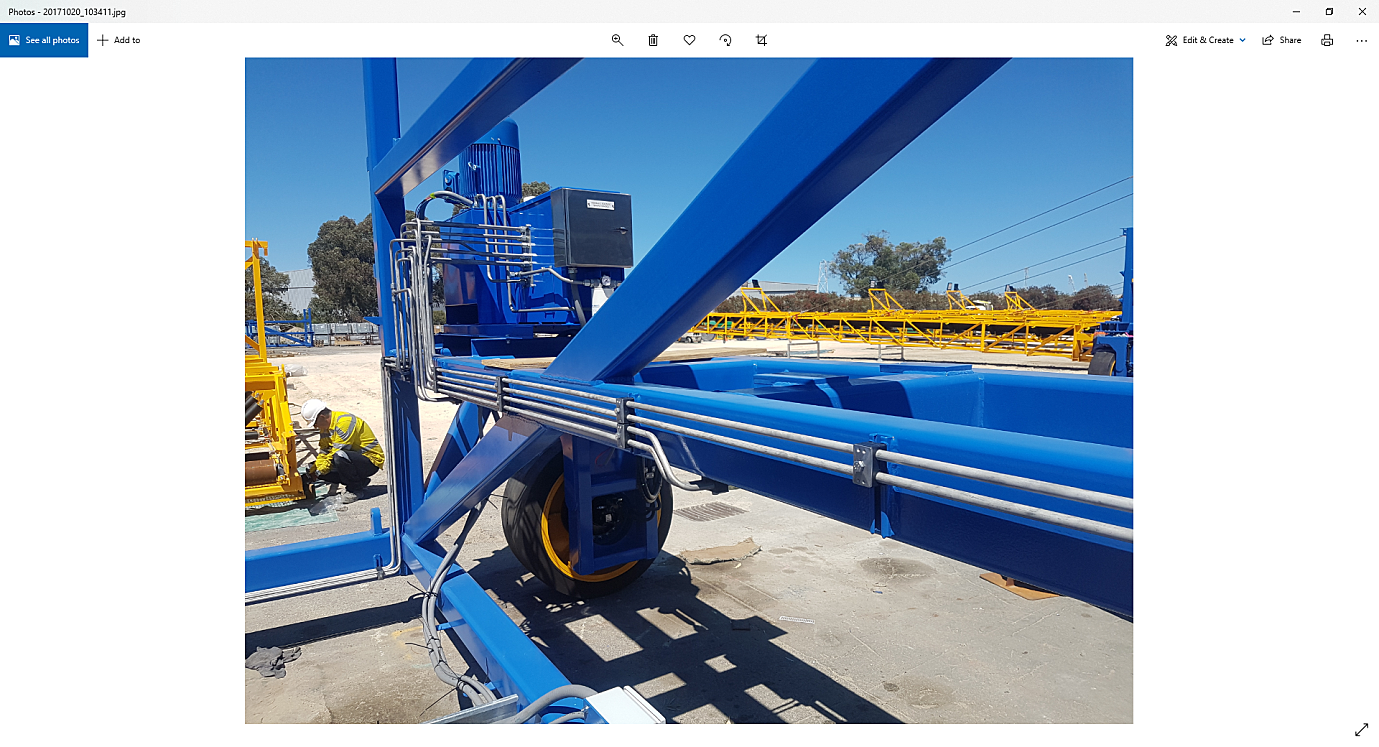

CBH : CLS and DOG Stackers – HPUs, Actuators, Wheel drives, Hydraulic manifolds, Tube kits.

Industry : Agricultural

Hytube designed a new hydraulic system for CBH mobile grain conveyors in 2015, and have continued to supply similar designs each year. Hytube custom build the Hydraulic Power Units, wheel drives and actuator assemblies for multiple units in our workshop, from our detailed assembly drawings.

Hytube fabricate all tubing within the workshop to form assembly kits. Hytube install the tube assembly kits on the Stacker machines at the Client/Build site, and complete final testing of the equipment.

The project is closely managed and monitored to ensure all equipment is supplied to meet the Client build schedule, and within budget.

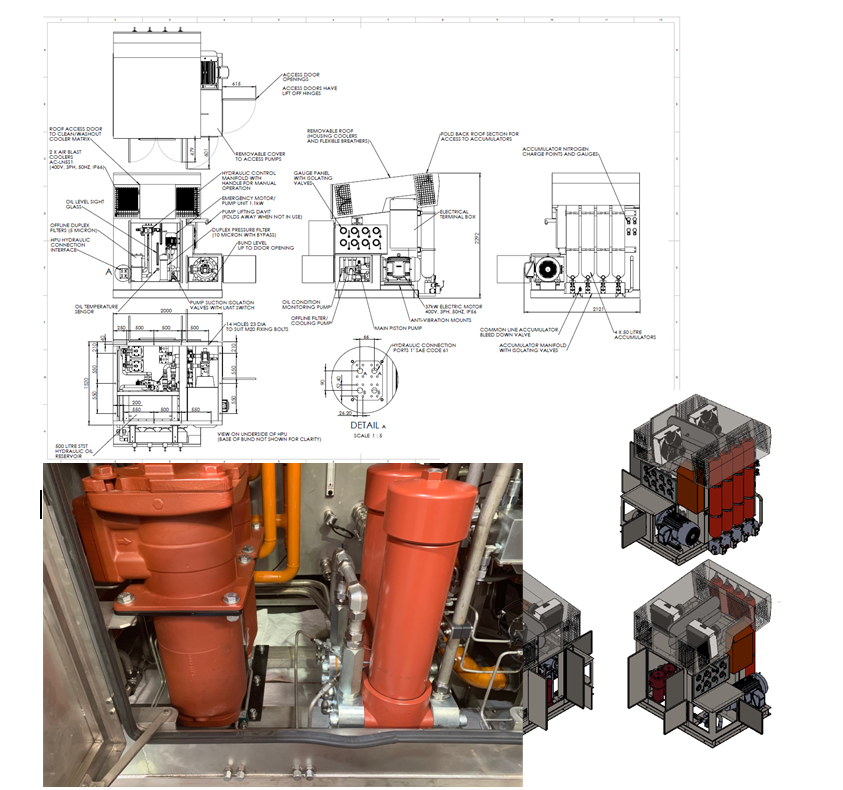

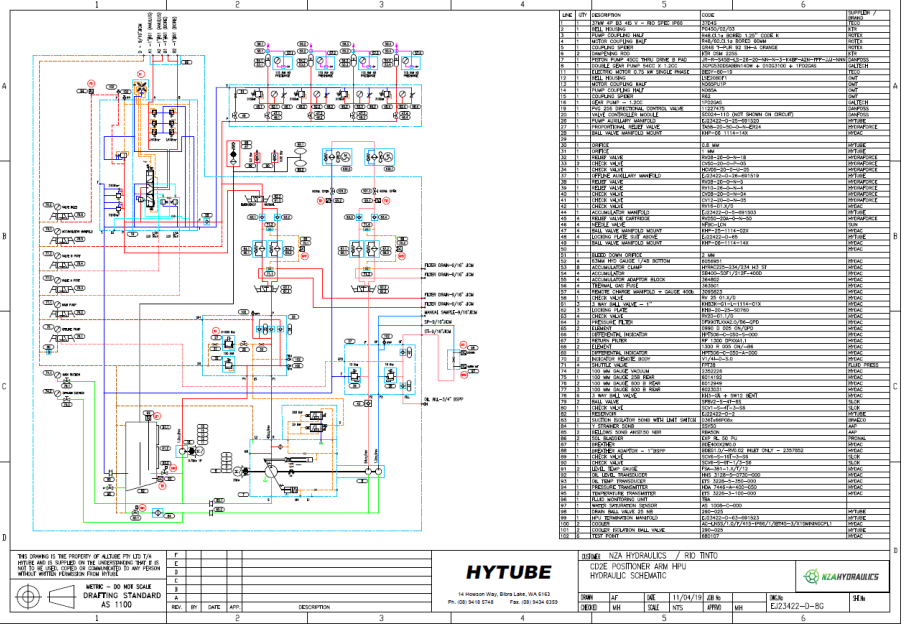

NZA Hydraulics : Train Positioner Arm for CD2E, East Intercourse Island

Industry:Mining

Hytube designed, built & FAT the Train Positioner Arm Hydraulic Power Unit to specific customer specifications, within our workshop. Stainless steel enclosure and structure, designed to withstand cyclone conditions.