About Us

What We Do

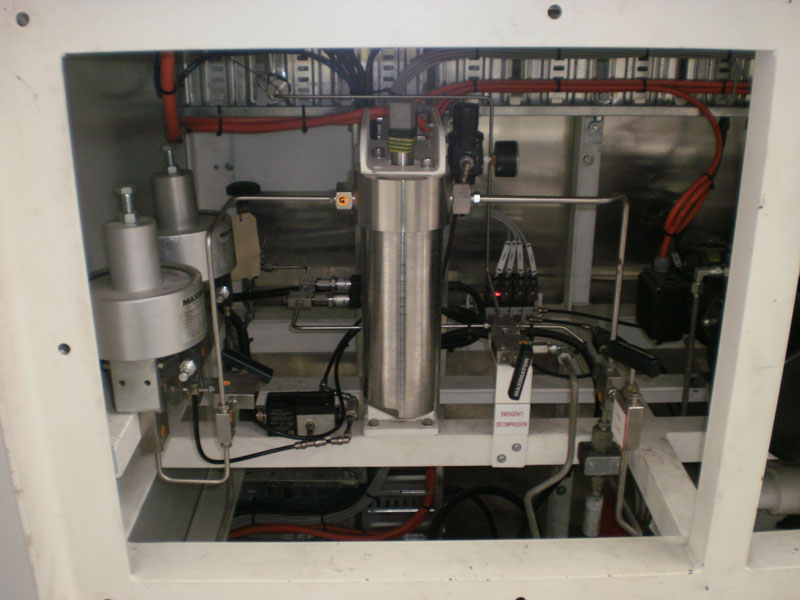

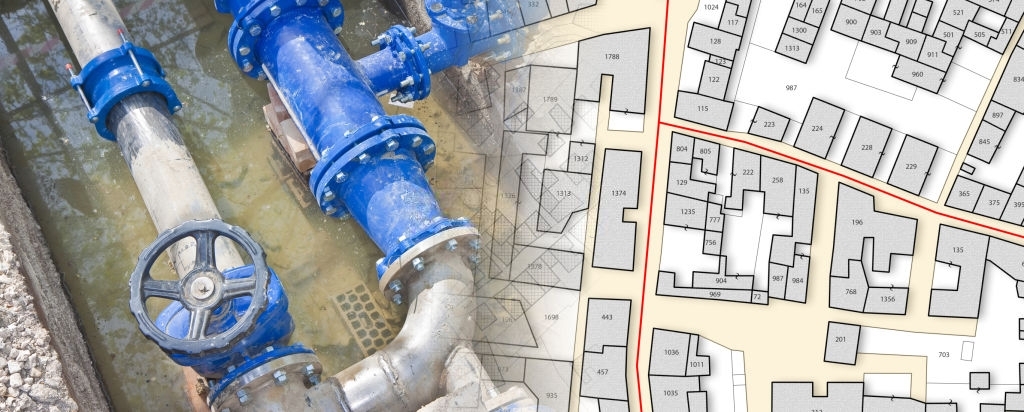

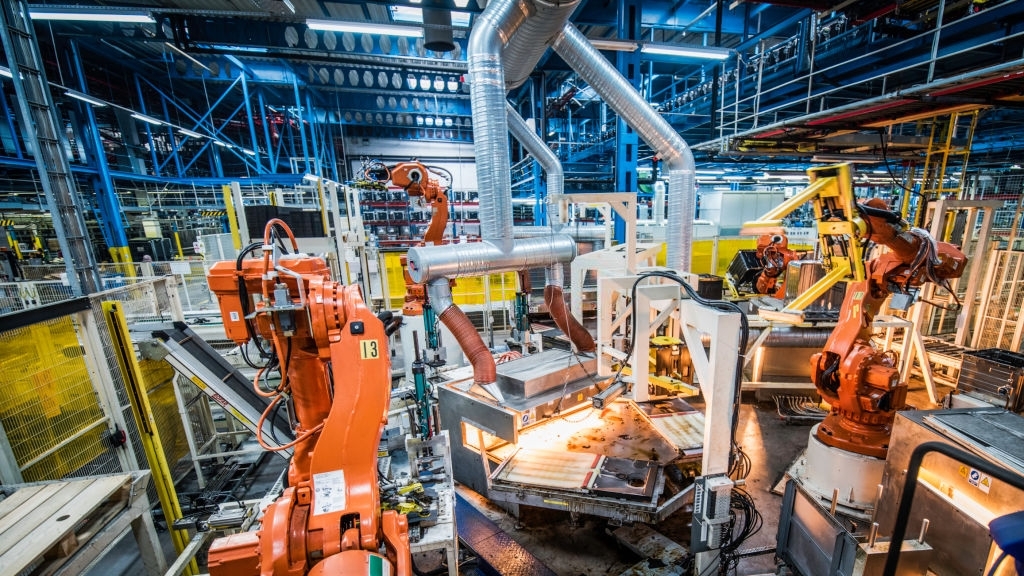

Hytube are a specialist provider of hydraulic equipment, piping and tube services. Our services include, manufacturing, installation, testing, servicing and repair, design and engineering, product sales and equipment hire.

Why Choose Hytube

With a commitment to maintaining a high level of skills, knowledge and experience throughout the business, Hytube can help with your requirements. From definition of initial scope and detailed specifications, through design and engineering solutions, to procurement and manufacturing, all our capabilities are in-house, thus reducing interfaces and therefore delays, costs, and errors. Our on-site services provide installation and testing, ensuring a seamless transition to site and continuity of the project, by having the ability to manage the whole schedule. The benefits also include having a single point of responsibility, and a complete, consistent, quality documentation package.

Hytube are also a stockist and supplier of pipe, tubes, hoses & fittings, enabling us to be competitive when supplying complete systems and packages.

Our Reputation

Hytube has established a reputation for excellent service and quality, with our ability to provide solutions and adapt to changing demands quickly, whilst maintaining consistency in our work, without compromising on safety.

We build effective relationships with our clients through regular communication and understanding of their needs, with a willingness to support them throughout the project life cycle, whilst demonstrating our commitment and integrity.

Safety

Hytube are committed to providing a safe working environment for all employees and maintains a responsibility to protect the health and welfare of everyone who works with us. By promoting and providing ongoing training and support, we continuously improve our performance in safety management and risk assessments, to consistently provide and maintain safe working practices.

Safety is a priority to us, our goal is to ensure zero incidents or accidents in the work place and on site. In addition to understanding and following lockout/tagout procedures for safe de-energisation, our employees are trained to identify the hazards associated with stored energy which are common to hydraulic systems, and also to verify components within pressure containment systems are suitably rated, and restrained, before operating/testing.